23

апр

What is Serial Number management in SAP ?

Thursday, March 16, 2017. Plant Maintenance - Equipment with AVLB and ESTO system status. ESTO: This means that the equipment is in stock at your facility. It could be any plant or location, but it is now in stock, and you can no longer perform an inbound.

The SAP serial number functionality allow us to managing serialized stock material keeping. SAP Serial number management is mainly focuses on Inventory tracking. Always the material number and serial number combination is unique in system. The SAP serial number component contributes in following business area.

1. Material Management

2. Production Planning

3. Quality Management

4. Sales and distribution

5. Plant Maintenance

1.How to change the serial number status from ECUS EDEL ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and serial number. Please give the input based on below screen

Michael Farr (translator). Keygen antidote 8 v2 rocket 3. San Francisco: Last Gasp.

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter

Step 4 : Now status changed into “ESTO”. now Click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”

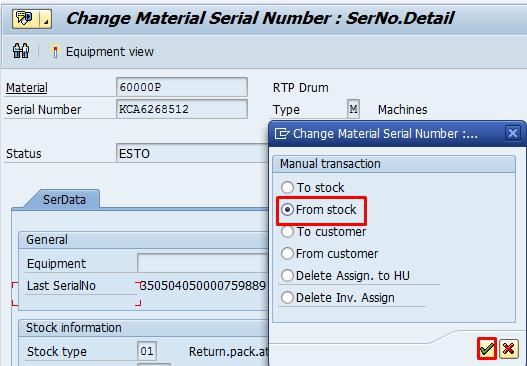

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

2.How to change the serial number status from ECUS ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and Serial number. Please give the input based on below screen

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter. ECUS ESTO means, serial number for this material available in customer location.

Step 4 : Now status changed into “ESTO”. Then click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”In Goods issue, we can use only “ESTO” status material.

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

In this document I will be discussing the automatic serializing of a material, while Goods Receipt.

Consider material 757, which has been assigned Serial No Profile = PM.

In the serial no profile, we have 2 settings for “Equipment Requirement”.

- Proposal: w/o equipment

- Always with equipment

For the above serial no profile PM, Equipment requirement is defined as “Without Equipment”.

So the common expectation would be that when we do GR of this material, serial no will be automatically created. And the equipment no will not be generated because of “without equipment” definition.

Doing GR for 757, using 501 movement type. (Using 501, to avoid PR, PO process) Microsoft windows english spelling package.

Since the Material Master 757 has been assigned with a serial no profile, all stock of 757 is supposed to be serialized on GR. Therefore, when we add 757 in MIGO, a serial no tab automatically appears.

Serial number can be mentioned manually, as well as automatically by checking the check box.

Check the serial numbers created for material 757 in IQ08.

We can see that serial no 1 to 5 has been created and also equipment numbers 10005707 to 10005711 has been created automatically.

So point to be noted here is that, on GR serial no is created and also EQUIPMENT NO is created, contrary to the expectation of “no equipment would be created”.

However, if we try to open eq master in IE02, the equipment doesn’t exist.

Here, we need to do something called as “Activation of Equipment View”. Only then we can access eq master in IE02.

Double click the equipment no in the IQ08 screen.

We can see that Equipment field in the above screen is still empty.

Now click the “Equipment View” (activate) button.

On pressing the “Activate Eq View” button, we get this screen. Now the eq no is shown as 10005707. This means that the eq view has been created for this serialized material (serial no 5 for material 757).

Just Save and the equipment view will be saved.

Now go to IE02 for eq 10005707. Equipment master is now available and can be accessed.

So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

Further if Eq Req = Always without equipment.

In this case, the process is exactly same, only difference being that we do not need to activate the equipment view, since it is already activated.

On GR

IE02: 10005713

Further point to be noted is that in both cases Equipment status is ESTO. (Equipment in stores)

Business meaning of ESTO is that, this material 758 serial no 2 is inventorized in store. And for using this material as an equipment, the status of the equipment should be AVLB. For doing this the material should be Goods Issued from stores to the required cost center (Account assignment cost center).

Doing GI, for the material 758, serial no 2 for cost center 1000.

After GI of serialized material:

- From Inventory side: Material stock will be issued and stock in MMBE will reduce by 1

- From PM side: Equipment which was earlier lying in stores, has been issued and is now AVAILABLE (AVLB) for installation.

Further, we need to maintain the Organizational data of this equipment manually, by maintaining plant, cost center, planning plant and work center.

Final Take Away:

- 1. So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

- 2. In both cases (with and w/o eq) equipment status will be ESTO. For using this equipment, this serialized material has to be Goods Issued to required cost center. On GI, eq status changes to AVLB

- 3. In both cases, we need to maintain the Organizational data manually for the equipment.

Popular Posts

What is Serial Number management in SAP ?

Thursday, March 16, 2017. Plant Maintenance - Equipment with AVLB and ESTO system status. ESTO: This means that the equipment is in stock at your facility. It could be any plant or location, but it is now in stock, and you can no longer perform an inbound.

The SAP serial number functionality allow us to managing serialized stock material keeping. SAP Serial number management is mainly focuses on Inventory tracking. Always the material number and serial number combination is unique in system. The SAP serial number component contributes in following business area.

1. Material Management

2. Production Planning

3. Quality Management

4. Sales and distribution

5. Plant Maintenance

1.How to change the serial number status from ECUS EDEL ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and serial number. Please give the input based on below screen

Michael Farr (translator). Keygen antidote 8 v2 rocket 3. San Francisco: Last Gasp.

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter

Step 4 : Now status changed into “ESTO”. now Click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

2.How to change the serial number status from ECUS ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and Serial number. Please give the input based on below screen

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter. ECUS ESTO means, serial number for this material available in customer location.

Step 4 : Now status changed into “ESTO”. Then click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”In Goods issue, we can use only “ESTO” status material.

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

In this document I will be discussing the automatic serializing of a material, while Goods Receipt.

Consider material 757, which has been assigned Serial No Profile = PM.

In the serial no profile, we have 2 settings for “Equipment Requirement”.

- Proposal: w/o equipment

- Always with equipment

For the above serial no profile PM, Equipment requirement is defined as “Without Equipment”.

So the common expectation would be that when we do GR of this material, serial no will be automatically created. And the equipment no will not be generated because of “without equipment” definition.

Doing GR for 757, using 501 movement type. (Using 501, to avoid PR, PO process) Microsoft windows english spelling package.

Since the Material Master 757 has been assigned with a serial no profile, all stock of 757 is supposed to be serialized on GR. Therefore, when we add 757 in MIGO, a serial no tab automatically appears.

Serial number can be mentioned manually, as well as automatically by checking the check box.

Check the serial numbers created for material 757 in IQ08.

We can see that serial no 1 to 5 has been created and also equipment numbers 10005707 to 10005711 has been created automatically.

So point to be noted here is that, on GR serial no is created and also EQUIPMENT NO is created, contrary to the expectation of “no equipment would be created”.

However, if we try to open eq master in IE02, the equipment doesn’t exist.

Here, we need to do something called as “Activation of Equipment View”. Only then we can access eq master in IE02.

Double click the equipment no in the IQ08 screen.

We can see that Equipment field in the above screen is still empty.

Now click the “Equipment View” (activate) button.

On pressing the “Activate Eq View” button, we get this screen. Now the eq no is shown as 10005707. This means that the eq view has been created for this serialized material (serial no 5 for material 757).

Just Save and the equipment view will be saved.

Now go to IE02 for eq 10005707. Equipment master is now available and can be accessed.

So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

Further if Eq Req = Always without equipment.

In this case, the process is exactly same, only difference being that we do not need to activate the equipment view, since it is already activated.

On GR

IE02: 10005713

Further point to be noted is that in both cases Equipment status is ESTO. (Equipment in stores)

Business meaning of ESTO is that, this material 758 serial no 2 is inventorized in store. And for using this material as an equipment, the status of the equipment should be AVLB. For doing this the material should be Goods Issued from stores to the required cost center (Account assignment cost center).

Doing GI, for the material 758, serial no 2 for cost center 1000.

After GI of serialized material:

- From Inventory side: Material stock will be issued and stock in MMBE will reduce by 1

- From PM side: Equipment which was earlier lying in stores, has been issued and is now AVAILABLE (AVLB) for installation.

Further, we need to maintain the Organizational data of this equipment manually, by maintaining plant, cost center, planning plant and work center.

Final Take Away:

- 1. So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

- 2. In both cases (with and w/o eq) equipment status will be ESTO. For using this equipment, this serialized material has to be Goods Issued to required cost center. On GI, eq status changes to AVLB

- 3. In both cases, we need to maintain the Organizational data manually for the equipment.

What is Serial Number management in SAP ?

Thursday, March 16, 2017. Plant Maintenance - Equipment with AVLB and ESTO system status. ESTO: This means that the equipment is in stock at your facility. It could be any plant or location, but it is now in stock, and you can no longer perform an inbound.

The SAP serial number functionality allow us to managing serialized stock material keeping. SAP Serial number management is mainly focuses on Inventory tracking. Always the material number and serial number combination is unique in system. The SAP serial number component contributes in following business area.

1. Material Management

2. Production Planning

3. Quality Management

4. Sales and distribution

5. Plant Maintenance

1.How to change the serial number status from ECUS EDEL ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and serial number. Please give the input based on below screen

Michael Farr (translator). Keygen antidote 8 v2 rocket 3. San Francisco: Last Gasp.

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter

Step 4 : Now status changed into “ESTO”. now Click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

2.How to change the serial number status from ECUS ESTO To AVLB manualy ?

Step 1 : Go To – Transaction code : IQ02 and give Material and Serial number. Please give the input based on below screen

Step 2 : Click “EDIT” Menu and then select “Special serial no.functions” and click the “Manual Transaction”

Step 3 : Now we will get below POP up, then click the radio button “From Customer” and Press enter. ECUS ESTO means, serial number for this material available in customer location.

Step 4 : Now status changed into “ESTO”. Then click EDIT button and then select “Special serial no.functions” and click “Manual Transaction”In Goods issue, we can use only “ESTO” status material.

Step 5 : Now click the Radio button “From Stock” and Press enter.Now the status will be changed to “AVLB”

Step 6 : Now Status changed to “AVLB”, Then SAVE the serial number. Now we have user serial number for receiving the material.

In this document I will be discussing the automatic serializing of a material, while Goods Receipt.

Consider material 757, which has been assigned Serial No Profile = PM.

In the serial no profile, we have 2 settings for “Equipment Requirement”.

- Proposal: w/o equipment

- Always with equipment

For the above serial no profile PM, Equipment requirement is defined as “Without Equipment”.

So the common expectation would be that when we do GR of this material, serial no will be automatically created. And the equipment no will not be generated because of “without equipment” definition.

Doing GR for 757, using 501 movement type. (Using 501, to avoid PR, PO process) Microsoft windows english spelling package.

Since the Material Master 757 has been assigned with a serial no profile, all stock of 757 is supposed to be serialized on GR. Therefore, when we add 757 in MIGO, a serial no tab automatically appears.

Serial number can be mentioned manually, as well as automatically by checking the check box.

Check the serial numbers created for material 757 in IQ08.

We can see that serial no 1 to 5 has been created and also equipment numbers 10005707 to 10005711 has been created automatically.

So point to be noted here is that, on GR serial no is created and also EQUIPMENT NO is created, contrary to the expectation of “no equipment would be created”.

However, if we try to open eq master in IE02, the equipment doesn’t exist.

Here, we need to do something called as “Activation of Equipment View”. Only then we can access eq master in IE02.

Double click the equipment no in the IQ08 screen.

We can see that Equipment field in the above screen is still empty.

Now click the “Equipment View” (activate) button.

On pressing the “Activate Eq View” button, we get this screen. Now the eq no is shown as 10005707. This means that the eq view has been created for this serialized material (serial no 5 for material 757).

Just Save and the equipment view will be saved.

Now go to IE02 for eq 10005707. Equipment master is now available and can be accessed.

So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

Further if Eq Req = Always without equipment.

In this case, the process is exactly same, only difference being that we do not need to activate the equipment view, since it is already activated.

On GR

IE02: 10005713

Further point to be noted is that in both cases Equipment status is ESTO. (Equipment in stores)

Business meaning of ESTO is that, this material 758 serial no 2 is inventorized in store. And for using this material as an equipment, the status of the equipment should be AVLB. For doing this the material should be Goods Issued from stores to the required cost center (Account assignment cost center).

Doing GI, for the material 758, serial no 2 for cost center 1000.

After GI of serialized material:

- From Inventory side: Material stock will be issued and stock in MMBE will reduce by 1

- From PM side: Equipment which was earlier lying in stores, has been issued and is now AVAILABLE (AVLB) for installation.

Further, we need to maintain the Organizational data of this equipment manually, by maintaining plant, cost center, planning plant and work center.

Final Take Away:

- 1. So the meaning of Setting “Eq Requirement = Without Equipment” is that:

- Equipment number will be automatically created, along with serial no, on doing GR.

- Equipment master is still not accessible in IE02, till the equipment view is activated manually.

- 2. In both cases (with and w/o eq) equipment status will be ESTO. For using this equipment, this serialized material has to be Goods Issued to required cost center. On GI, eq status changes to AVLB

- 3. In both cases, we need to maintain the Organizational data manually for the equipment.